In its latest issue, FMJ magazine worked with Great Forest to offer a deep dive into waste audits. The report, Getting to the Bottom of Waste, uses data and case studies pulled from hundreds of Great Forest waste audit investigations conducted around the world each year.

It summarizes everything a facility manager or sustainability officer needs to know about waste audits and how they can be used to understand how waste is generated and discarded, and what to do to improve efficiency, and reduce waste and costs.

As businesses reopen across the country and adjust to changing rules and post-lockdown realities, waste audits are even more important to help businesses understand how their waste content is changing, and what to do to manage it more effectively.

If those who control information rule the world, waste audits are the key to effective waste management.

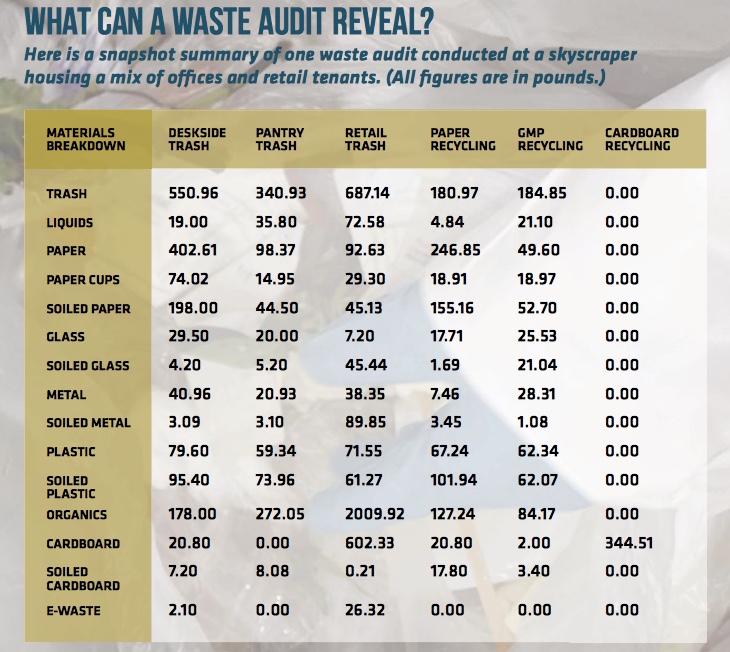

What Can A Waste Audit Reveal? Here’s A Peek At Some Hard Data

To get to the bottom of waste, a facility or business needs to understand what is being thrown out in all their waste streams, from trash to materials being collected for recycling and composting. This involves some down-in-the-dirt investigative work called a waste audit, which delivers data that every facility manager needs to make informed decisions.

The article explains what a waste audit is, how to plan for one, and why waste audits are so important in a world where waste costs are rising and expected to keep going up.

But most importantly, the report shares actual hard data from a waste audit and reveals how the data is analyzed and interpreted. Case studies are also included to show how waste audits has helped businesses.

Click here to read the full report that includes an analysis of the results of this waste audit Great Forest conducted at a skyscraper in NYC with a mix of offices and retail tenants.

Learn More:

- Waste Audit Facts and Benefits: Why Every Business Needs A Waste Audit

- Over 100 Waste Audits Reveal 77% Of Commercial Trash Is Not Trash At All!

- Waste Audit Reveals What’s In Your Waste Stream – 77% of “Trash” Is NOT Trash At All

- Case Study: Waste Audits Uncover Sizable Revenue Stream For Global Brand